In the field of vacuum technology, rotary vacuum pumps are a common type of pump that is widely used for a variety of applications. These pumps are known for their ability to generate high levels of vacuum and maintain a consistent vacuum pressure, making them ideal for a range of industrial and scientific applications. In this blog, we will focus on one type of rotary vacuum pump – the rotary vane vacuum pump – and explore how it works and where it is used.

What is a Rotary Vane Vacuum Pump?

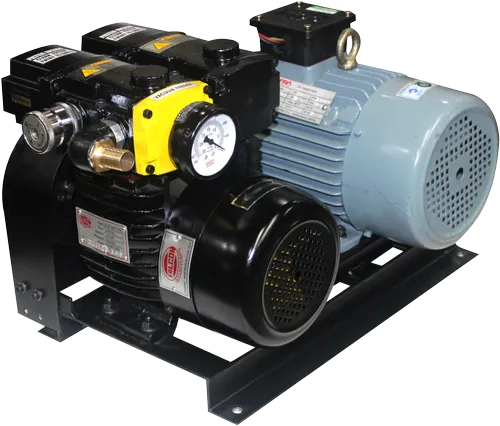

It’s a type of positive displacement pump that uses a series of rotating vans to create a vacuum. The pump consists of a housing, a rotor with vanes, and an inlet and outlet port. The rotor is located off-centre in the housing and rotates at high speed, creating a seal between the vanes and the housing.

As the rotor rotates, the vanes move in and out of their slots in the rotor, creating a vacuum in the space between the vanes. The vacuum draws gas or air through the inlet port and into the space between the vanes. As the rotor continues to rotate, the gas is compressed by the vanes until it is expelled through the outlet port at a higher pressure.

Rotary vane vacuum pumps can generate a vacuum pressure of up to 10^-3 bar, making them suitable for a wide range of applications. They are commonly used in the chemical, pharmaceutical, and food industries, as well as in scientific research, where a consistent vacuum pressure is required.

Advantages:

There are several advantages, first, they are relatively simple and easy to operate, making them an ideal choice for applications where a high level of automation is not required. Second, they are reliable and have a long service life, provided they are properly maintained. Third, they can operate continuously without the need for frequent shutdowns, making them suitable for continuous industrial processes.

Disadvantages:

Despite their many advantages, these also have some disadvantages. One of the main disadvantages is that they can be noisy, which can be a problem in some applications. Additionally, they can generate a significant amount of heat during operation, which can be a problem if the pump is located in a small or poorly ventilated space.

These are a popular type of rotary vacuum pump that is widely used in a range of industrial and scientific applications. They offer several advantages, including simplicity, reliability, and continuous operation. However, they also have some disadvantages, such as noise and heat generation. If you are considering using it for your application, it is important to carefully consider its advantages and disadvantages to determine whether it is the right choice for your needs.