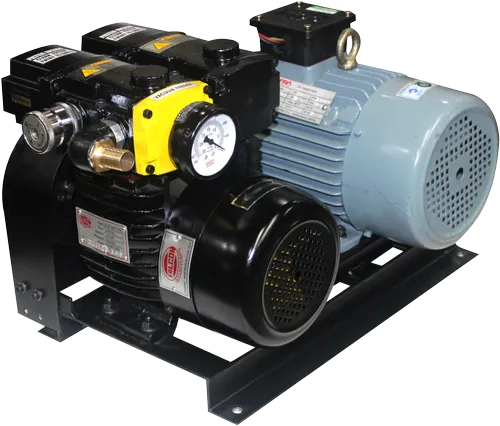

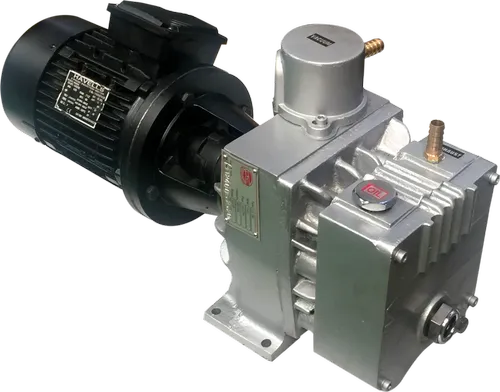

In the world of Industrial Vacuum Pumps systems, oil lubricated vacuum pumps continue to be a preferred choice for many businesses. Their reliability, efficiency, and adaptability make them a cornerstone in various applications across industries. This blog explores the numerous benefits and diverse applications of Oil lubricated vacuum pumps, shedding light on why they are a top choice for industrial processes.

Oil lubricated vacuum pumps are renowned for their exceptional performance in creating and maintaining vacuum conditions. One of the primary benefits of these pumps is their superior lubrication system, which ensures smooth operation and reduces wear and tear on the pump components. The oil not only lubricates but also acts as a coolant, dissipating heat generated during the vacuum process. This dual function enhances the longevity and efficiency of the pump, making it a cost-effective choice for long-term use.

Another advantage of Oil lubricated vacuum pumps is their ability to achieve high vacuum levels with minimal noise. The oil helps in damping vibrations and reducing operational noise, providing a quieter working environment. This feature is particularly beneficial in industries where noise control is crucial, such as in laboratory settings or in facilities requiring a serene working atmosphere.

The versatility of Oil lubricated vacuum pumps makes them suitable for a wide range of industrial applications. They are commonly used in processes such as distillation, evaporation, and degassing, where high vacuum levels are essential. Additionally, these pumps are vital in the manufacturing of semiconductor devices, where precise vacuum conditions are required for the deposition and etching processes.

In the food and beverage industry, Oil lubricated vacuum pumps play a crucial role in packaging and preserving products. The vacuum created by these pumps helps in removing air from packaging, thereby extending the shelf life of perishable goods and maintaining product freshness. Similarly, in the pharmaceutical industry, these pumps are used for the drying and processing of medications, ensuring product quality and efficacy.

Despite the advancements in vacuum pump technology, Oil lubricated vacuum pumps remain a top choice due to their proven reliability and effectiveness. Their ability to handle various operational conditions and provide consistent performance underscores their importance in industrial processes. Whether it’s for creating high-quality vacuum environments or enhancing operational efficiency, Oil lubricated vacuum pumps continue to deliver exceptional results, cementing their status as a preferred solution in numerous industrial applications.

In conclusion, the benefits of these vacuum pumps—from their efficient lubrication and cooling to their versatile applications—make them a valuable asset in industrial processes. Their ability to provide reliable and high-performance vacuum solutions ensures they remain a top choice for industries worldwide